Description

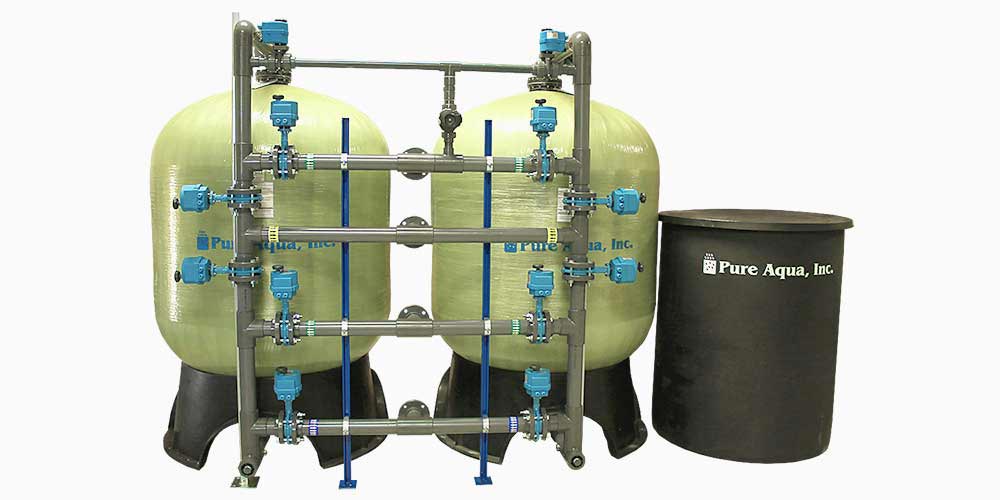

Aqua Components manufactures and delivers industrial water softener systems for the provision of clean water for any of your industrial applications. We have a comprehensive list of happy clients throughout the world that have realized the usefulness of our water softener solutions.

Aqua Components industrial water softener systems treat the water by removing hardness using resin. The resin replaces the hardness in the water with salt which is regenerated periodically. The softened water can then pass through an RO system to remove the salt without the risk of scaling. Softeners can be used in a variety of services including: industrial, municipal, and institutional applications.

Industrial Water Softener System Capacity

- The SF-110F series softeners are designed as fully automatic units either with timer or meter control. The timer controller initiates automatic regeneration features a choice of 7 or 12 day calendar wheels. Time of regeneration and length of time for each regeneration cycle are fully adjustable.

- The metered models start regeneration based on the total gallons used.

- The FRP mineral tank is engineered for a 150 psi working pressure and is tested to 160 psi.

- A premium grade sulfanated nonphenolic polystyrene type resin is contained in the mineral tank. The resin will deliver 30,000 grains per cubic foot when brined at a rate of 15 lbs. per cubic foot.

- The brine tank is a combination of high density polyethylene tank and a brine valve, including an air eliminator valve and a safety brine refill shut off to prevent tank overflow.

- The under drain utilizes either a hub & lateral or a header & lateral system to evenly distribute water and prevent resin loss, and to insure minimal pressure drop at peak flow rates.

| System Specifications: | ||

|

|

|

|

Model # |

|

Flow Rate (GPM) |

Valve and Pipe Size |

Resin Qty. (ft) |

Tank Size |

Salt Storage (lbs.) |

Approx. Weight (lbs) |

|||

|

Service |

BW |

|||||||||

|

Cont. |

Peak |

Softener |

Brine |

|||||||

|

WSF14-90-1 |

90,000 |

15 |

25 |

6 |

1″ |

3 |

14×65 |

24×50 |

900 |

400 |

|

WSF16-120-1 |

120,000 |

16 |

27 |

7 |

1″ |

4 |

16×65 |

24×50 |

900 |

450 |

|

WSF18-150-1.5 |

150,000 |

25 |

40 |

9 |

1.5″ |

5 |

18×65 |

24×50 |

900 |

575 |

|

WSF21-210-1.5 |

210,000 |

30 |

50 |

12 |

1.5″ |

7 |

21×65 |

24×50 |

900 |

650 |

|

WSF24-300-1.5 |

300,000 |

40 |

60 |

16 |

1.5″ |

10 |

24×72 |

24×50 |

900 |

985 |

|

WSF24-300-2 |

300,000 |

65 |

120 |

16 |

2″ |

10 |

24×72 |

24×50 |

900 |

1,000 |

|

WSF30-450-1.5 |

450,000 |

40 |

70 |

25 |

1.5″ |

15 |

30×72 |

30×50 |

1,400 |

1,470 |

|

WSF30-450-2 |

450,000 |

65 |

120 |

25 |

2″ |

15 |

30×72 |

30×50 |

1,400 |

1,490 |

|

WSF36-600-2 |

600,000 |

65 |

120 |

35 |

2″ |

20 |

36×72 |

30×50 |

1,400 |

1,910 |

|

WSF36-600-3 |

600,000 |

120 |

270 |

35 |

3″ |

20 |

36×72 |

30×50 |

1,400 |

1,980 |

|

WSF42-900-2 |

900,000 |

65 |

120 |

48 |

2″ |

30 |

42×72 |

30×50 |

1,400 |

2,800 |

|

WSF42-900-3 |

900,000 |

120 |

270 |

48 |

3″ |

30 |

42×72 |

30×50 |

1,400 |

2,835 |

|

WSF48-1200-2 |

1,200,000 |

65 |

120 |

63 |

2″ |

40 |

48×72 |

50×60 |

4,500 |

3,650 |

|

WSF48-1200-3 |

1,200,000 |

120 |

270 |

63 |

3″ |

40 |

48×72 |

50×60 |

4,500 |

3,670 |

|

WSF63-1500-3 |

1,500,000 |

120 |

300 |

119 |

3″ |

50 |

63×86 |

50×60 |

4,500 |

4,170 |

| For more information, please view/download our “Data Sheet” | ||||||||||

| Standard Options: | Available Options: |

|

|

| The ideal applications for the SF-110F series include: | ||

|

|

|

Here at Aqua Components LLC, we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.